"*" indicates required fields

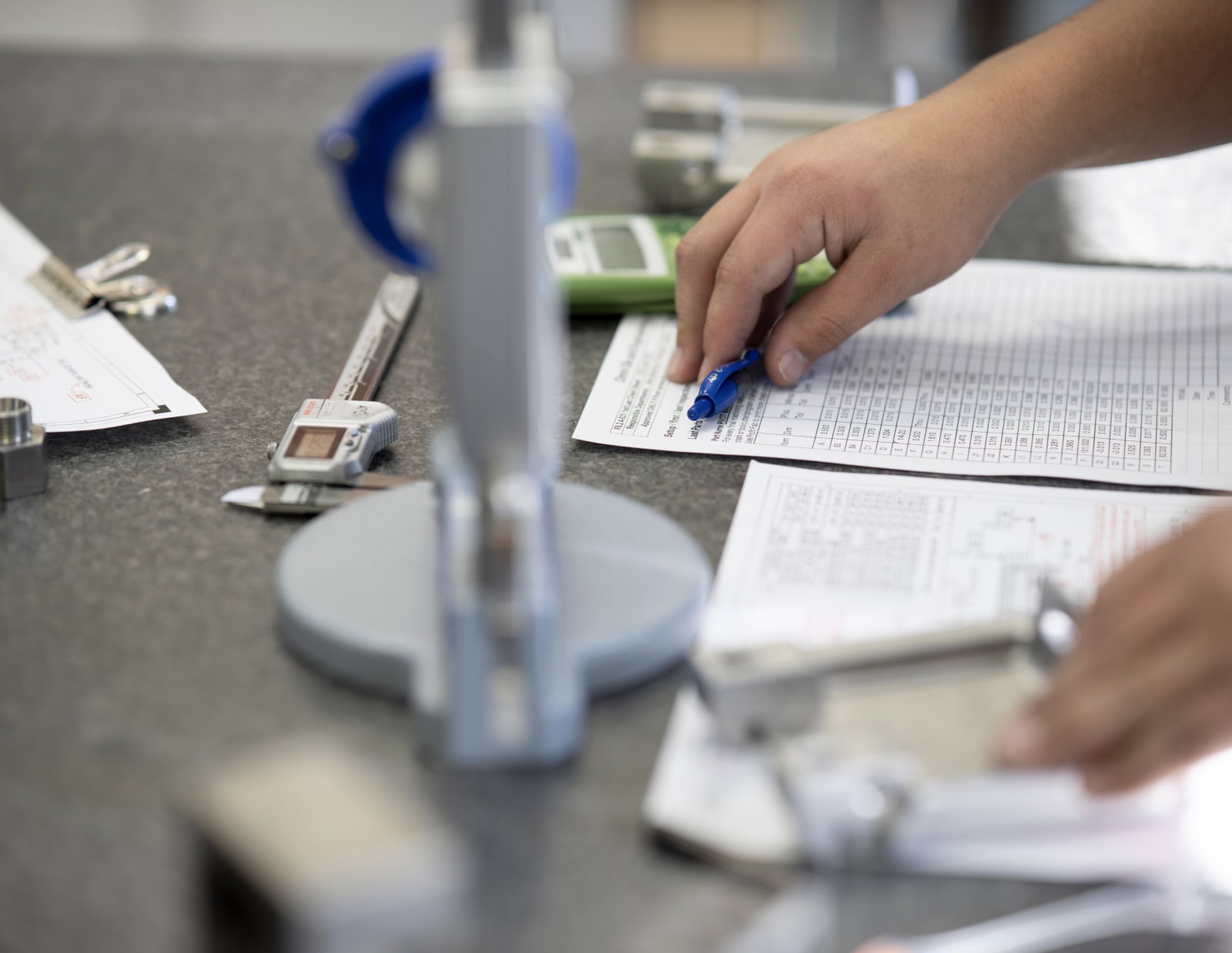

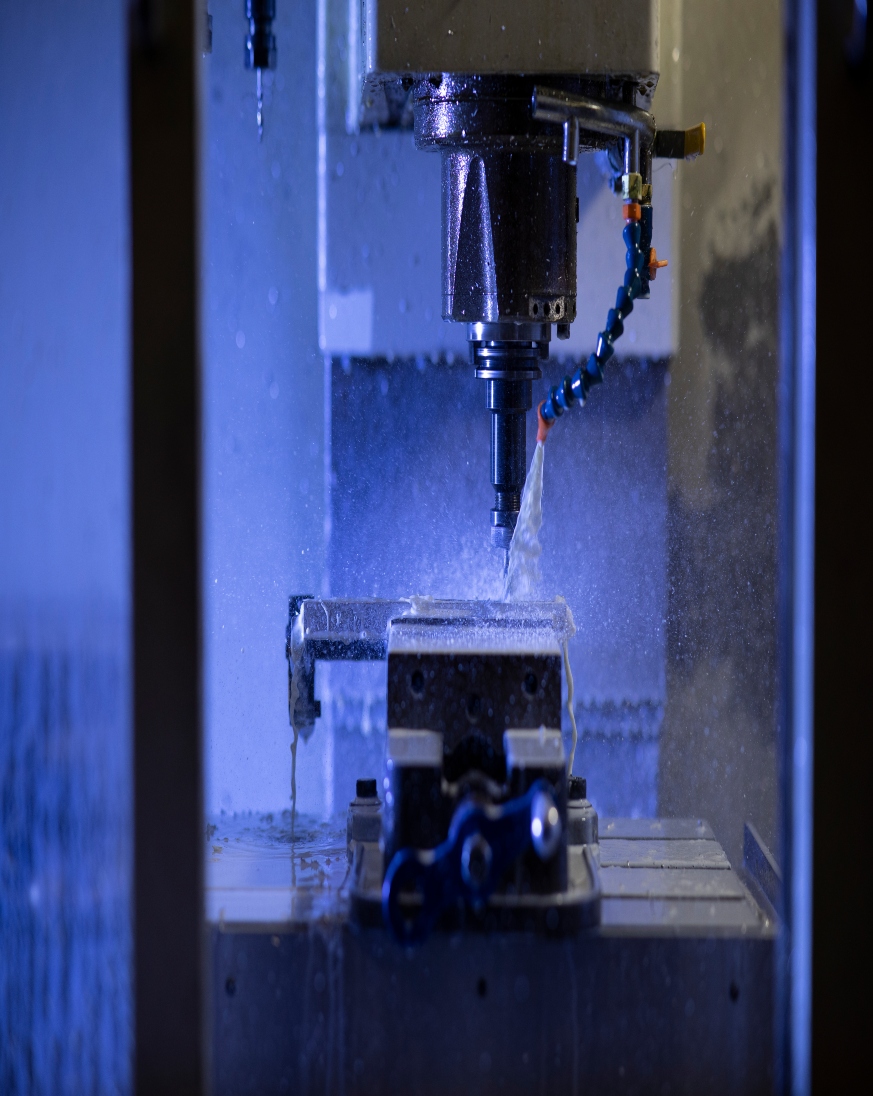

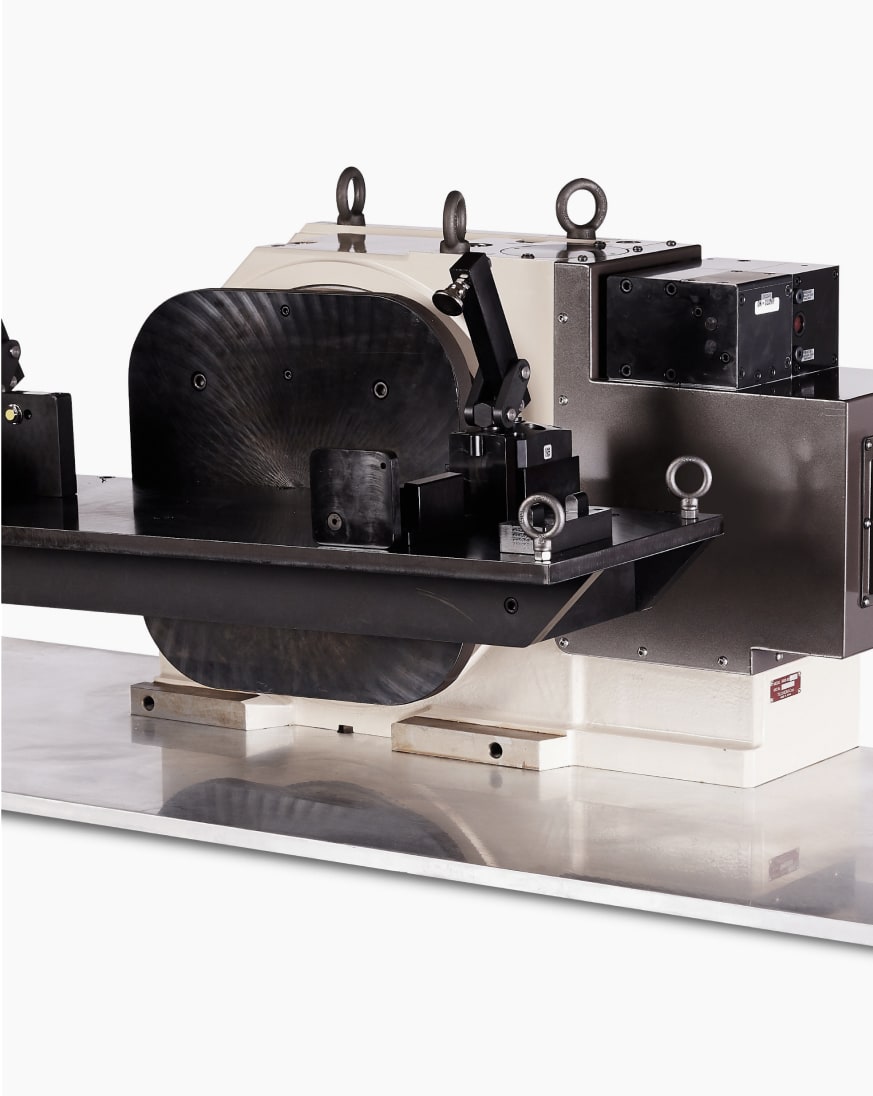

At Omni, we begin with a Customer-Centric Approach. This means actively listening to thoroughly understand what our customer needs are and develop solutions that will meet those needs. We encourage our customers to provide regular feedback to ensure all expectations are understood and met. Lastly, our customers can expect a well-documented process-oriented approach. Altogether, the end result is predictably reliable and meets all specifications. Many companies can get it right if you give them unlimited time, at Omni, it needs to right and on time, every time. Trust your next project to Omni and experience the Omni quality difference.