Precision

Machining

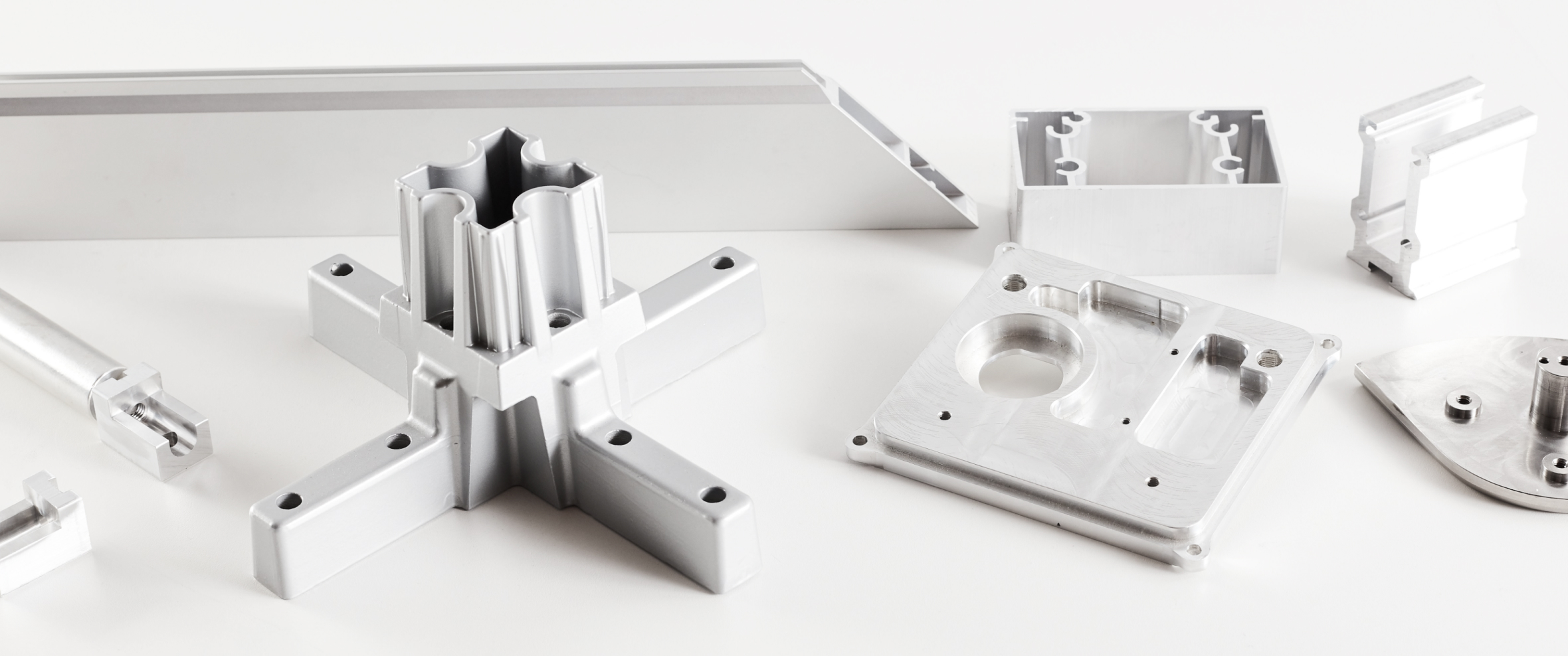

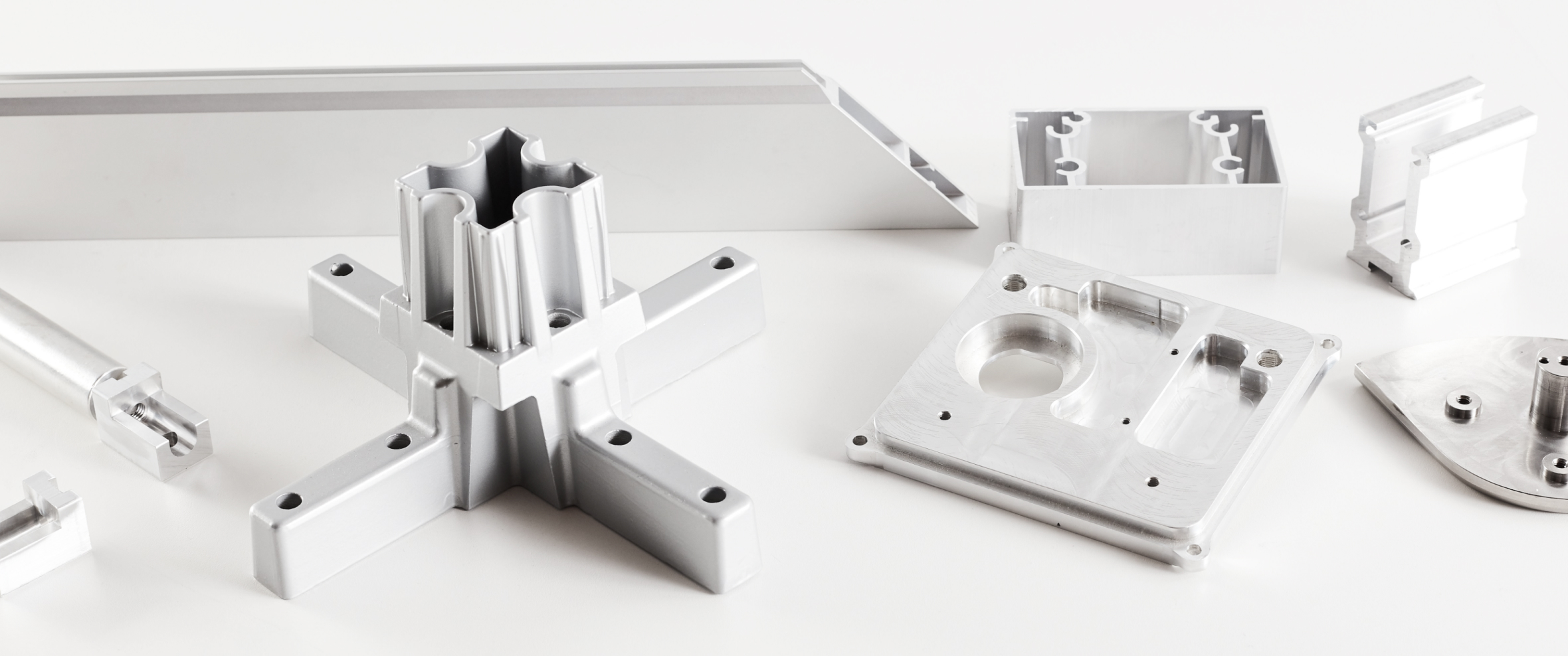

Omni is a best practice precision machining facility that delivers full-service precision machined parts and components. We offer 3, 4, 5 and 6-axis machining to meet the highest standards of quality and accuracy based on your requirements. With 18 CNC Machining Centers and CNC Lathes housed in a climate-controlled facility spanning 54,000 square feet, we are equipped to handle a wide variety of materials and projects with precision and efficiency. Our advanced capabilities and dedication to excellence have established Omni Precision Components as an industry leader.

Our Machining Capabilities

Aluminum Castings

Raw Aluminum Machining

Steel Machining

Lathe Components

Stainless Steel Machining

Plastic Machining

Flow Drilling

Extrusion Machining

Why Choose Omni for Precision Machining?

Advanced Technologies

At Omni, we utilize the latest machining technologies to provide comprehensive solutions for your production needs. Our climate controlled facility is equipped with advanced 3, 4, 5, and 6-axis machining centers, enabling us to handle complex geometries and intricate designs with exacting precision.

Material Expertise

For more than six decades we have worked with a wide range of materials, including metals, plastics, and advanced composites. Whether you need parts made from steel, aluminum, titanium, or specialized alloys, our team has the expertise to deliver high-quality results.

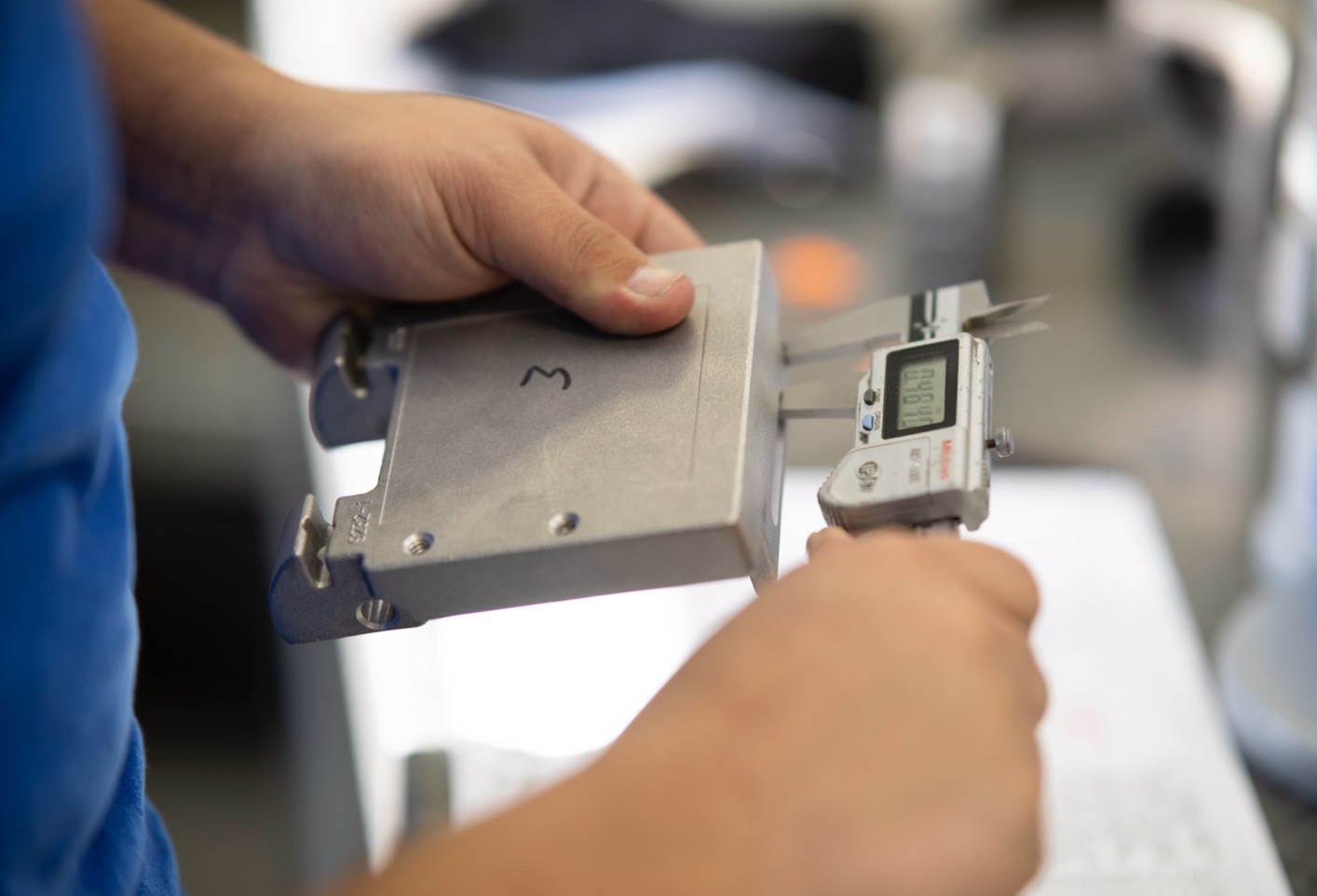

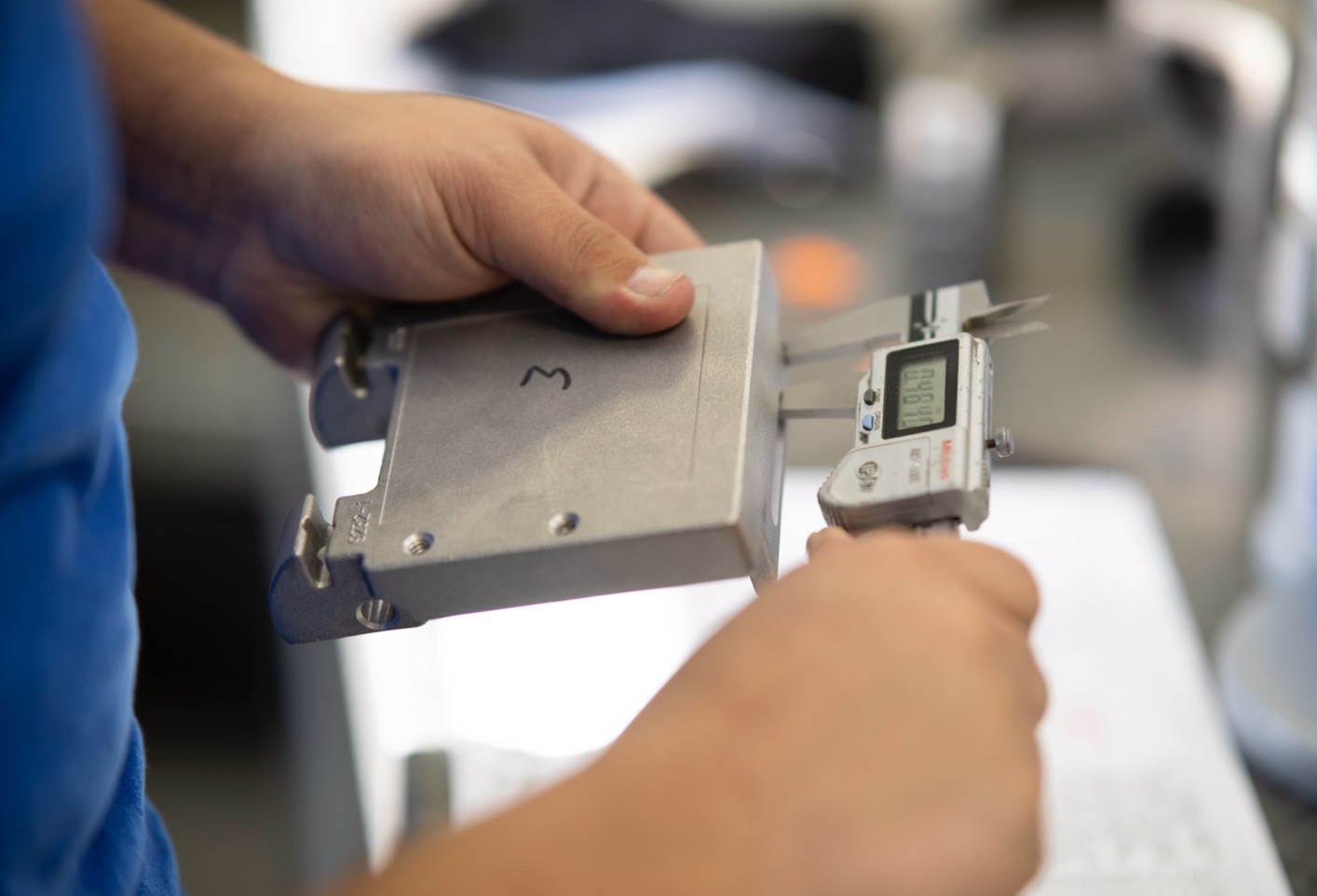

Quality Assurance

ISO 9001:2015 Certified

Being certified as an ISO 9001-15 and a and a CMM1 manufacture, quality is at the core of everything we do. As a certified ISO 9001:2015 manufacturer, we adhere to the highest standards of quality management. This certification reflects our commitment to customer satisfaction and delivering consistent high-quality components.

Our quality assurance processes include detailed inspections and testing on the production floor and in our well-equipped quality lab. From PPAP to final part inspection we ensure that each component meets the required specifications.

Omni’s Experienced Team

In addition to technical competency, our skilled team of machinists, engineers, and quality control experts bring decades of experience and expertise to every project. We work closely with our customers to understand their needs and deliver solutions that meet their required specifications.

Best Practices & Continuous Improvement

As a best practice precision machining facility we are committed to continuous improvement and adopting the latest industry best practices. Our team stays up-to-date with robust training and new advancements in precision machining technologies and processes to ensure that we provide the best possible solutions to our customers.

Customer Satisfaction

At Omni, customer satisfaction is our highest priority. We build long-term relationships with our customers by providing exceptional service, reliable delivery, and superior quality. For over 60 years we have held to the motto, "your success is our success," and we are dedicated to helping you achieve your objectives.

Our Precision Machining Process

Our precision machining process is optimized for precision and efficiency. We employ rigorous quality control measures from our quality lab to on floor inspections. Advanced software and automation machinery enables us to produce consistent, reliable parts, while reducing lead times and costs.

1. Initial Consultation and PPAP Approval

We begin with a thorough consultation to understand your project requirements. Our highly experienced quality team will work with you through the PPAP approval process to ensure all critical aspects of production are meticulously planned and approved by our customer.

2. Production Planning

Our production planning involves detailed ERP resource allocation and workflow optimization to ensure efficient and timely production. We leverage our advanced equipment and skilled technicians to meet your deadlines while maintaining exceptional quality.

3. Machining and Fabrication

Utilizing our advanced CNC Machining Centers and Lathes we will machine your parts with precision ending in a final result that is precise and on time. Our capabilities enable us to handle complex geometries and high-volume production runs.

4. Quality Assurance

Our technicians conduct rigorous quality checks throughout the production process. We utilize advanced computerized measurement tools and techniques to verify that each part meets the specified tolerances and quality standards. Detailed reports are provided to keep you informed.

5. Final Inspection and Delivery

Before delivery, the appropriate inspections are completed to ensure all parts meet your required specifications. We want to ensure that your components are delivered on time and ready for immediate use in your applications.

Industries We Serve

Omni provides production machining services to a diverse range of industries, including: