"*" indicates required fields

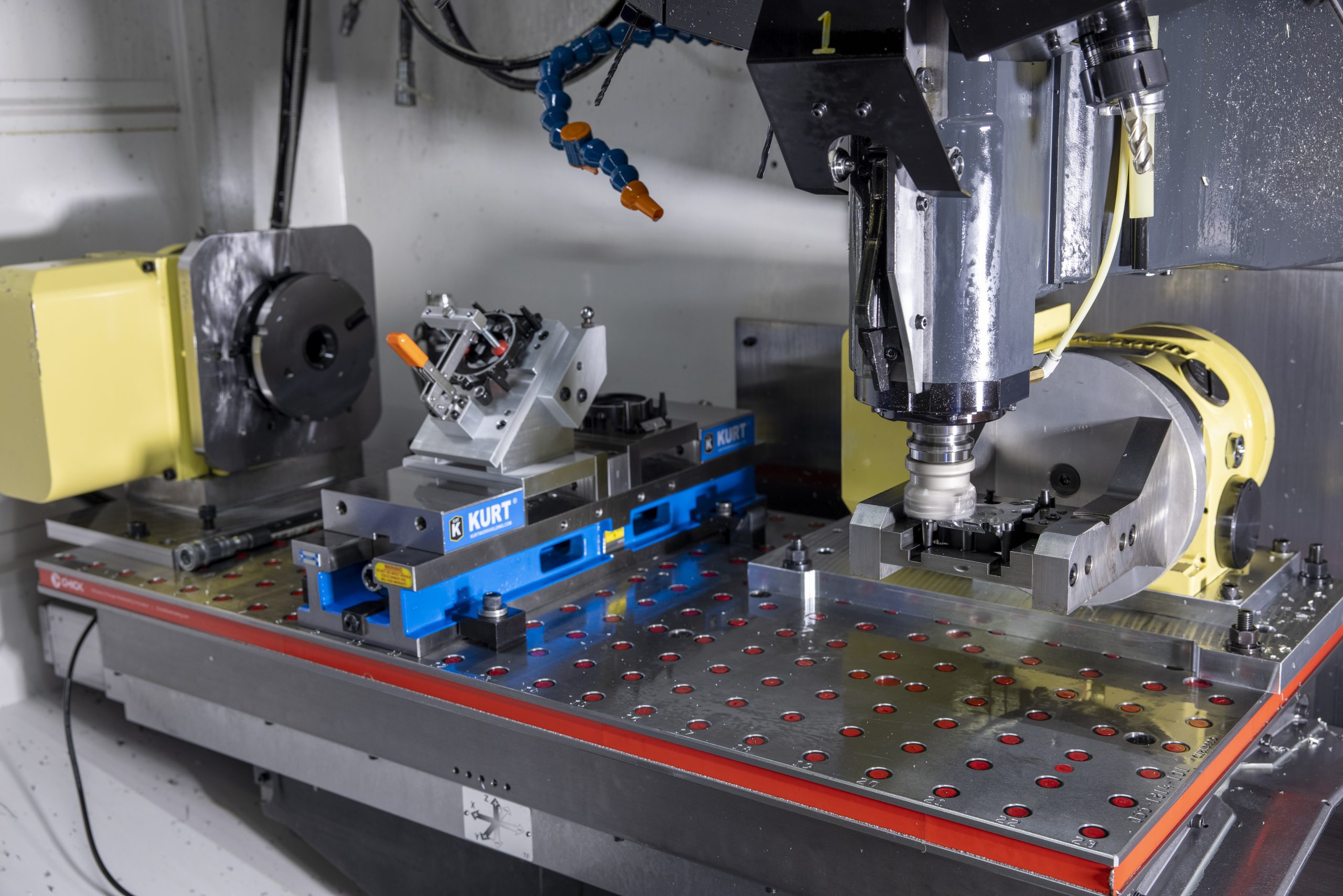

Precision machining stands as a pinnacle in the world of manufacturing, employing computer-controlled machine tools to produce parts with unparalleled accuracy. This high-velocity machining process is essential for creating components that demand tight tolerances, intricate designs, or both. Executed by our skilled precision machinists and through the efficiency of our lights-out robotics, precision machining at Omni is a subtractive manufacturing process that starts with a solid block of material and meticulously carves out the desired shape with a cutting tool.

At its core, precision machining revolves around two critical elements: a top-tier cutting tools and a high precision Computer Numerical Control (CNC) machine. The cutting tool must possess precision ensuring the final product aligns perfectly with the intended dimensions.

Steps in the Precision Machining Process

From selecting the right tool paths to the final cut, each phase requires high precision removal. Different methods and equipment come into play, ensuring that the end result meets the stringent standards set by the customer.

Materials Fit For Precision

Metals, including aluminum, stainless steel, and titanium, are commonly chosen for precision machining due to their inherent strength, weight, durability, and thermal conductivity. These materials withstand the cutting forces exerted during machining while maintaining dimensional stability.

On the other hand, plastics, such as nylon, Delrin, or PEEK, offer a different set of advantages in precision machining. These materials are valued for their lightweight nature, corrosion resistance, and versatility in achieving intricate designs. However, machinists must navigate challenges such as managing heat buildup during the machining process to prevent material deformation.

Get in Touch With Omni

Experience the efficiency of Omni's CNC precision machining in West Michigan, where precision meets productivity. Our CNC technology boosts output while allowing our experts to tackle detailed designs with ease. Essential for local industries, Omni's machining supports the aerospace sector with key safety components, the medical field with pinpoint-accurate devices, and contributes to automotive, electronics, and defense through seamless component integration. For precise manufacturing solutions tailored to West Michigan, choose Omni's CNC expertise.